How to maintain maize milling machine on a daily basis?

.jpg)

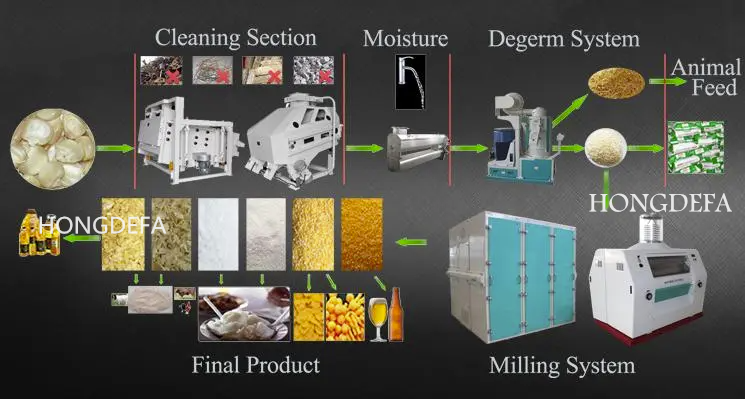

M aize milling machine is a deep processing maize milling machine that processes corn into flour or grits. Since the maize milling machine has a long operating time and is mostly located indoors, the maize milling machine will have some problems such as powder jamming and spitting out slag over time. This reflects the importance of daily maintenance of the maize milling machine . So how to maintain corn processing maize milling machine on a daily basis? 1. Cleaning and maintenance Cleaning is the basis of maize milling machine maintenance and can effectively prevent maize milling machine failures caused by impurity accumulation. First of all, a detailed cleaning plan should be formulated to clarify the cleaning cycle and cleaning method of each maize milling machine . For parts that directly contact corn raw materials, such as feed ports, screens, conveyor belts, etc., food-grade detergents should be used for cleanin...